Vietnam quartz Slabs

Our Vietnam quartz slabs are exclusively tailored for the North American market, engineered with premium craftsmanship for local residential and commercial demands. First, they feature ultra-low resin content, the core of superior performance and long-term stability for daily use. Moreover, the slabs deliver exceptional scratch resistance, standing up to frequent friction without marks, and rigid anti-warping properties to stay intact with no deformation in varying temperatures. In addition, we offer rich and diverse color patterns, including classic and modern designs to fit North American luxury kitchen and bathroom aesthetics. Also, the slabs perfectly match regional home renovation and high-end interior trends, with consistent quality to meet your bulk sourcing needs for countertops and surfacing projects.

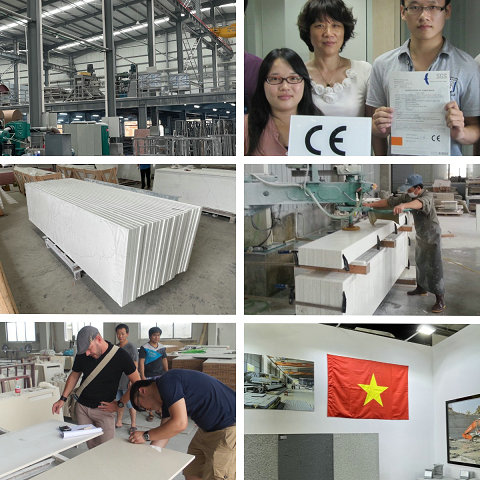

About Us

We are a Vietnam-based professional quartz stone trading company, with years of focused experience in serving the North American market and an in-depth grasp of local procurement standards and aesthetic trends. First, we have built stable in-depth partnerships with over 20 premium quartz stone factories across Vietnam, enabling strict production control and sufficient bulk supply capacity. Moreover, we boast an extensive and diverse range of quartz slab color patterns, covering classic and modern styles to fit North American residential and commercial interior design needs. In addition, our products feature unbeatable cost-effectiveness with competitive pricing, while strictly controlling quality to meet regional market norms. Also, we provide a formal quality warranty period for all orders, offering reliable after-sales support for your procurement. Besides, our professional team inspects each batch of goods strictly, guaranteeing stable product performance to fully meet your customized and bulk sourcing demands in the North American market

Quartz surfaces slab

Our quartz stone slabs are custom-tailored for North American quartz stone distributors, with a comprehensive product system to meet your diverse sourcing and sales needs. First, our color patterns fully cover the classic and popular designs of world-renowned brands like Caesarstone, Silestone and Hanstone, perfectly aligning with North American mainstream aesthetic trends. Moreover, we offer a tiered pricing system ranging from low to high, adapting to your different market positioning and profit demands for various customer groups. In addition, our slabs come with a complete range of specifications, supporting bulk standard orders and flexible customized size requirements. Also, all products ensure consistent color and quality, guaranteeing your stable supply for regional retail and engineering project needs.

Quartz stone countertops

Our quartz stone countertops are specially tailored for North American quartz distributors, with versatile applicability to meet diverse project and retail demands. First, they are ideal for kitchen countertops, bathroom vanities, and all residential and commercial countertop projects, fitting home renovation and commercial space decoration perfectly. Moreover, we offer a full range of styles, specifications and price tiers, adapting to your different customer groups and project positioning needs. In addition, we welcome in-depth distributor cooperation with flexible bulk supply policies and stable sourcing capacity. Also, our products feature reliable quality and consistent performance, with perfect after-sales support to help you expand the local countertop market efficiently and gain more business benefits.

Budget hotel projects

Our quartz stone countertops are specially engineered as the ideal matching solution for budget hotel projects, and we sincerely welcome in-depth cooperation with North American distributors. First, we adopt cost-effective premium materials, balancing excellent product performance and project cost control for budget hotels. Moreover, the countertops feature high-quality processing with smooth edges and consistent finish, perfect for hotel kitchen countertops, bathroom vanities and all interior matching needs. In addition, we boast stable bulk supply capacity to meet the large-quantity delivery demands of hotel renovation projects. Also, we provide complete after-sales support and reliable product quality assurance, ensuring your cooperation is worry-free in all aspects.

A professional Vietnam Quartz Slabs Supplier